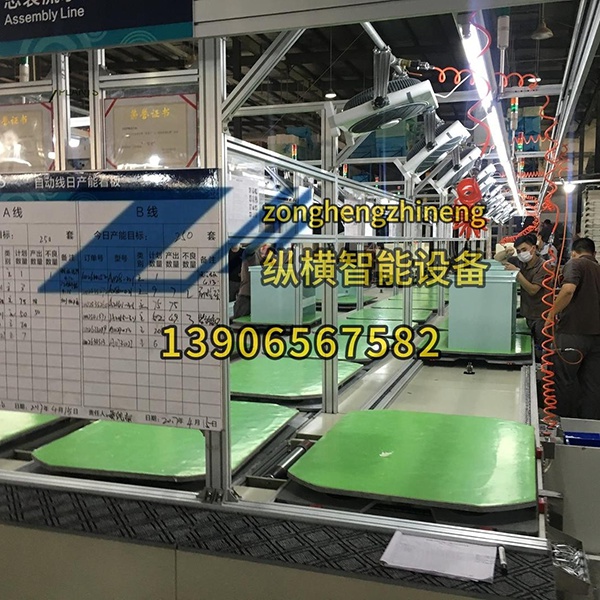

Stove Production Line

Stove production line refers to an automated assembly line process for manufacturing and assembling various types of gas stove products. This line helps to increase efficiency, reduce costs and ensure consistent product quality.

Details

1. Core Composition and Technical Characteristics

Hardware system

The stove automatic production line integrates a conveying unit, intelligent assembly equipment, and detection module, while also serving as the technical foundation for kitchen implements production line and cooking utensils production line.

Conveying unit: Adopting chain plate line, speed doubling chain or AGV (automatic guided vehicle), it realizes accurate positioning and continuous flow of cooker bottom shell, panel, burner and other parts in stove automatic production line, as well as components in kitchen implements production line and cooking utensils production line. The system is compatible with mixed-flow production of different specification products across the household kitchen appliance category.

Intelligent assembly equipment:

Mechanical arm: Used in stove automatic production line and other kitchen implements/cooking utensils production lines, it handles high-precision operations like burner installation and sealant coating, with positioning error ≤ 0.1mm.

Automatic screw-locking machine (an essential automated equipment): Equipped with visual alignment system, it achieves 60 pcs/min locking efficiency in stove automatic production line, ensuring torque accuracy ±3% for both stoves and other kitchen utensils.

Welding equipment: Laser/argon arc welding machines (key automated equipment) connect stove heads, brackets, and similar components in cooking utensils production line, with weld strength ≥ 200MPa.

Detection module:

Gas tightness tester: A critical automated equipment for stove automatic production line, it uses helium mass spectrometry to detect leaks at 1×10⁻⁹ Pa・m³/s, ensuring zero leakage in gas systems of stoves and related household kitchen appliances.

Intelligent electronic control test bench: Monitors 30+ parameters (ignition success rate, energy efficiency, etc.) in real time for stove automatic production line and transfers data to MES, applicable to quality control in kitchen implements production line.

Software System

The industrial Internet platform (core of automated equipment integration) monitors equipment status (OEE ≥ 90%) and traces process parameters (5+ years storage) for stove automatic production line, kitchen implements production line, and cooking utensils production line.

Digital twin technology: Simulates stove automatic production line operations to verify process paths in advance, shortening new product debugging cycles by 30%+ for the household kitchen appliance industry.

2. Typical Process Flow

Parts pre-processing

In stove automatic production line and cooking utensils production line, plate processing uses CNC punching (±0.2mm accuracy) and bending (±1° angle error) for household kitchen appliance components like panels and shells. Surface treatment via electrostatic spraying ensures film thickness uniformity ±5μm across all lines.

Burner assembly (common to kitchen implements production line): Automatic press-fitting machines assemble fire covers and nozzles, with visual inspection ensuring 99%+ air hole alignment in stove automatic production line and similar products.

Modular assembly

Segmented assembly line design adapts to stove automatic production line and kitchen implements production line:

Front section: Installs valves and ignition needles in stoves, with anti-mis-feeding sensors (100% alarm rate) also used in cooking utensils production line for error prevention.

Middle section: Integrates electronic controls and panels using servo-driven presses (gap ≤ 0.5mm), a process shared by the household kitchen appliance category.

Back section: Completes wiring and accessory installation (e.g., pot holders) in 8-12 minutes for stoves, with similar efficiency in cooking utensils production line.

Whole process testing

Function test:Ignition test ( automatic production line): 99.5% success rate within 3 seconds, with high-speed cameras (2000fps) analyzing flame stability for household kitchen appliance safety.

Thermal efficiency test: Automatically adjusts gas flow to meet Grade 1 energy efficiency (≥63%) for stoves and compatible products in kitchen implements production line.

Reliability test: Simulates 100,000 ignitions and 48-hour high-temperature/humidity operation for stove automatic production line and cooking utensils production line, ensuring durability in the household kitchen appliance sector.

Packaging and Traceability

Automated packaging equipment with weighing detection (±50g) and anti-dull labeling serves stove automatic production line and kitchen implements production line, compatible with cartons/foam for household kitchen appliance shipment.

Traceability system: Unique QR codes on each product link to production data for automatic production line and cooking utensils production line, enabling full lifecycle tracking in the household kitchen appliance industry.