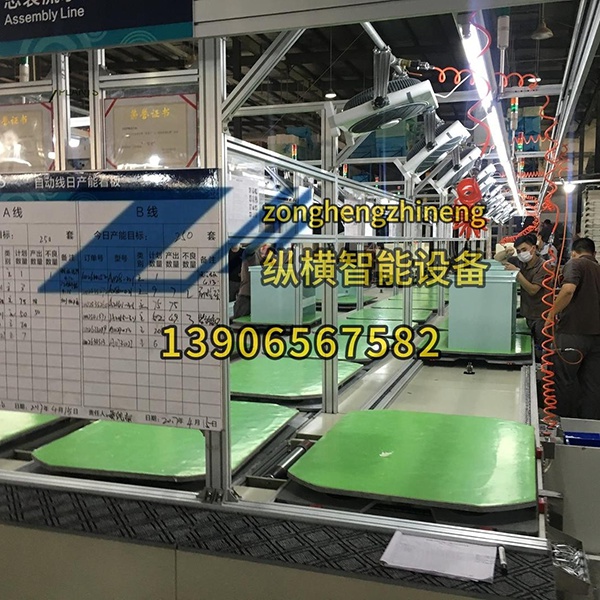

Hood Assembly Line

A hood assembly line is a type of automated assembly line in the production chain of the home appliance industry. It minimizes manual operations and dramatically improves production efficiency and product consistency.

Details

1.Technical Composition and Core Functions

The kitchen extractor hood assembly line integrates four key systems:

Conveying system: Utilizes speed chains or plate chains to transport hood components. In stainless steel hood assembly line, magnetic conveyors are often added for handling metal parts.

Assembly station: Robotic arms and automatic screw machines ensure precision, especially critical for smart range hoods assembly line with complex electronics.

Testing module: Airflow/noise testers validate performance - a standard for both kitchen extractor hood assembly line and premium stainless steel hood assembly line.

Packaging line: Automated cartoning protects finished products, whether from conventional or smart range hoods assembly line.

Example: An AI vision system in one smart range hoods assembly line achieved 99.8% defect detection accuracy.

2.Process Flow and Optimization

The stainless steel hood assembly line follows:

Pre-processing: Laser cutting ensures ±0.1mm precision for metal components.

Modular assembly: "One operator, one station" method, adapted for kitchen extractor hood assembly line variants.

Functional testing: 48-hour aging tests verify durability, mandatory for smart range hoods assembly line products.

Packaging: Moisture-proof solutions protect high-end outputs from stainless steel hood assembly line.

Optimization Directions:

Flexibility: AGVs enable rapid changeovers in kitchen extractor hood assembly line.

Intelligence: 5G connectivity transforms smart range hoods assembly line into digital twins.

Sustainability: Water-based paints reduce VOC emissions in stainless steel hood assembly line.

3.Typical Cases

In the field of high-end hood manufacturing, assembly line technology has realized intelligent and flexible production. For example, a company for high-end brands customized “double-layer speed chain” assembly line, through the elevator to achieve the work plate recycling, production efficiency increased by 50%; in the civilian hood market, a head of the brand adopts the U-shaped assembly line layout, a single hood production cycle compressed from 15 minutes to 9 minutes, the annual production capacity of more than 3 million units. The annual production capacity exceeded 3 million units. These cases show that assembly line technology is promoting the hood manufacturing to scale, customization direction.

4.Future Trends

The future hood assembly line will present three major technology trends:

Full-process intelligence: optimize the production beat through AI algorithms to achieve full-process automation from raw materials on line to finished products off line;

Modularized design: splitting the assembly line into independent functional modules, which facilitates quick adjustment to meet the production needs of different models of products;

Green manufacturing: the introduction of solar power supply systems and zero-emission processes to reduce carbon emissions in the production process. For example, the intelligent assembly line developed by an enterprise has achieved a 30% increase in energy utilization and a 70% reduction in VOCs emissions, setting a green manufacturing benchmark for the industry.