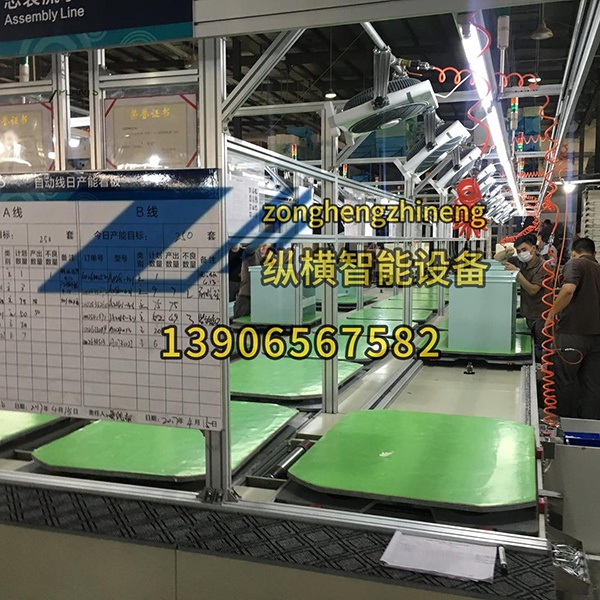

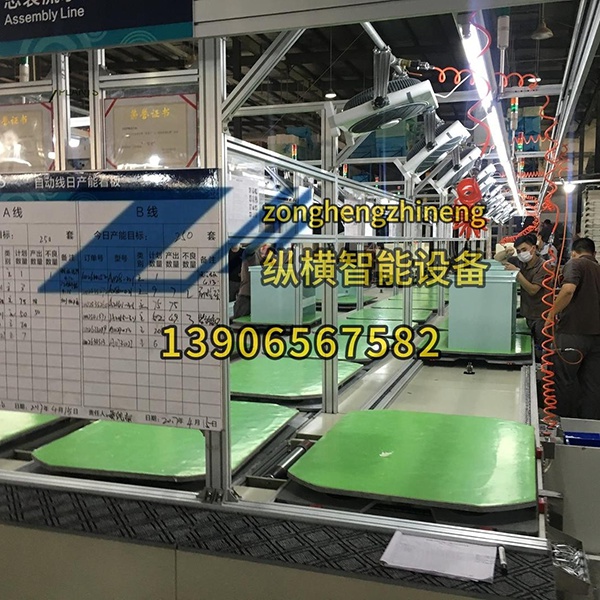

Hood Production Line

Hood production line is an automated production line specialized in producing range hoods. This type of production line is capable of efficiently assembling sheet metal into hood housings and internal components through stamping, welding, and painting processes.

Details

1. Production line planning and design

The hood automatic production line and kitchen extractor hood production line require systematic planning to ensure process efficiency.

Process flow sorting: The production process of hoods, includes raw material processing, parts manufacturing, general assembly, and testing. For example, in kitchen extractor hood production line, special processes like oil net punching and noise reduction component installation are integrated.

Equipment selection and purchasing: High-precision equipment is critical for automatic production line, such as automatic feeding machines (feeding accuracy ±0.5mm) and robot arms (repeatability ±0.05mm). For hood production line, additional equipment like anti-grease coating machines may be required.

Workshop Layout Optimization: 3D modeling tools (SolidWorks, AutoCAD) are used to design compact layouts for hood automatic production line, reducing material handling distance by 30%. In hood production line, zoning for noise-sensitive operations (e.g., fan testing) enhances safety.

2. Composition of production line

Speed chain conveying line: Widely used in hood production line (including hood automatic production line), this system offers high capacity (2000+ units/day) and stable speed (0.3-2m/min). In kitchen extractor hood production line, anti-static conveying surfaces prevent oil residue adhesion.

Automation equipment:Automatic welding machine: Essential for hood production line, ensuring airtight seams (leakage ≤10Pa·m³/h) in hood bodies.

Laser cutting machine: Used in hood production line to fabricate intricate oil filter meshes (hole size accuracy ±0.1mm).

Inspection equipment: Online inspection systems in automatic production line detect motor vibration (threshold ≤2.5mm/s), while kitchen extractor hood production line employs visual inspection for oil cup tightness (clearance ≤0.2mm).

3. Features of the production line

Modularized design

The hood automatic production line adopts modular units (e.g., motor assembly module, panel fitting module), enabling quick reconfiguration for different hood types. In hood production line, dedicated modules for installing grease filters and anti-backflow valves ensure process consistency.

Intelligent production

Industrial internet technology connects devices in hood automatic production line, enabling real-time monitoring of OEE (≥85%) and tool wear (alert when welding tip erosion >0.3mm). For kitchen extractor hood production line, AI algorithms optimize fan balancing parameters based on real-time noise data.

Data-based support

Both lines use MES systems to collect data: hood automatic production line tracks screw torque (5-10N·m) and assembly time (8-12min/unit), while hood production line analyzes oil filtration efficiency data to refine product designs.

4. Advantages of production line

Improve production efficiency:

Hood automatic production line reduces cycle time from 15 to 9 minutes/unit, with output increasing by 60%.

hood production line achieves 24/7 operation with minimal manual intervention, up from 16 hours/day in traditional lines.

Reduce production cost:

Labor costs decrease by 45% in hood automatic production line due to robotic assembly.

In kitchen extractor hood production line, automated material sorting cuts waste by 22%.

Improve product quality

Automated inspection in hood automatic production line lowers defect rates from 4% to 0.6%.

Kitchen extractor hood production line ensures noise levels ≤65dB through precise fan alignment (error ≤0.08mm).