Oven Production Line

The oven production line is a highly automated manufacturing system for the mass production of electric ovens. The line includes a number of key components and equipment to ensure efficient and high quality production.

Details

1. Product Introduction

The oven automatic production line integrates three core modules, with extended applications in restaurant commercial oven production line and digital stainless steel oven production line, all characterized by high degree of automation.

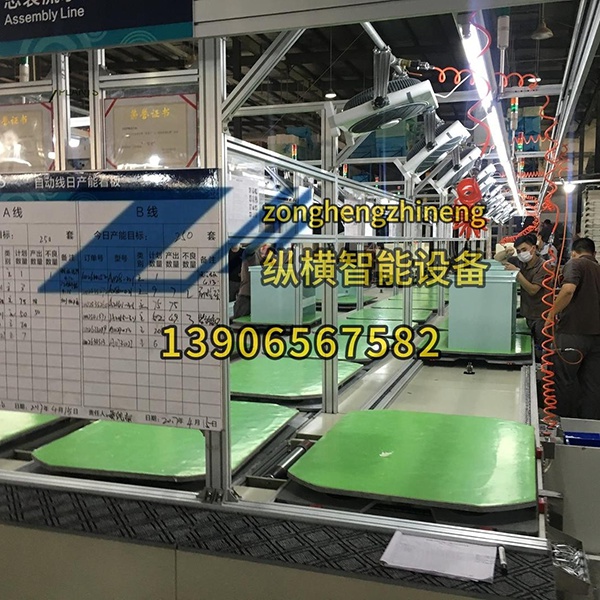

Oven assembly line: A key component of oven automatic production line, it uses chain plate conveyors (flat, low-friction surfaces) to transport oven accessories for assembly. In oven production line, food-grade stainless steel fixtures ensure corrosion resistance during assembly.

Oven aging test line: The core of restaurant commercial oven production line, this module simulates real-world usage (e.g., high-temperature baking for 24+ hours) with sections for transition, air-cooling, and burner testing. High degree of automation enables automatic parameter logging (current/voltage) for 100% product verification.

Oven unmanned packaging production line: A hallmark of high degree of automation, it achieves fully automatic boxing, sealing, and labeling, with oven production line featuring anti-scratch packaging for premium finishes.

2. Technical features

High degree of automation

The oven automatic production line eliminates 80% manual operations, from robotic assembly (positioning accuracy ±0.1mm) to AI-driven quality control in digital stainless steel oven production line. oven production line adds specialized modules for heavy-duty door hinge installation, all operated via touchscreen presets.

Precise Positioning and Clamping Mechanisms

Servo-driven clamps in oven automatic production line ensure ±0.05mm alignment for heating elements, critical for digital stainless steel oven production line’s seamless welds. In restaurant commercial oven production line, heavy-load fixtures secure industrial-grade chassis.

Powerful aging test

Aging test lines in restaurant commercial oven production line simulate 10,000+ hours of commercial use (240℃ continuous operation), with high degree of automation enabling real-time fault detection (response time <5s). Digital stainless steel oven production line adds humidity cycling for marine-grade durability testing.

Intelligent operation

Touchscreen controls in oven automatic production line support 50+ preset recipes (e.g., convection baking vs. static drying), while digital stainless steel oven production line integrates IoT connectivity for remote parameter adjustment.oven production line features multi-language interfaces for global deployment.

3. Application Scenario

Home appliance manufacturing: The oven automatic production line produces 2,000+ household ovens/day, with digital stainless steel oven production line catering to premium brands (e.g., fingerprint-resistant finishes). High degree of automation reduces labor costs by 35%.

Industrial production: For industrial ovens, restaurant commercial oven production line handles 1.5m³+ capacity models, using automated lifting systems (load capacity 2 tons) for heavy-duty assembly. High degree of automation ensures 24/7 curing process consistency.

Food processing: In bread production, oven automatic production line’s variable speed conveyors (0.1-3m/s) accommodate delicate pastries, while restaurant commercial oven production line’s dual-zone heating meets halal/kosher certification requirements with segregated baking cycles.