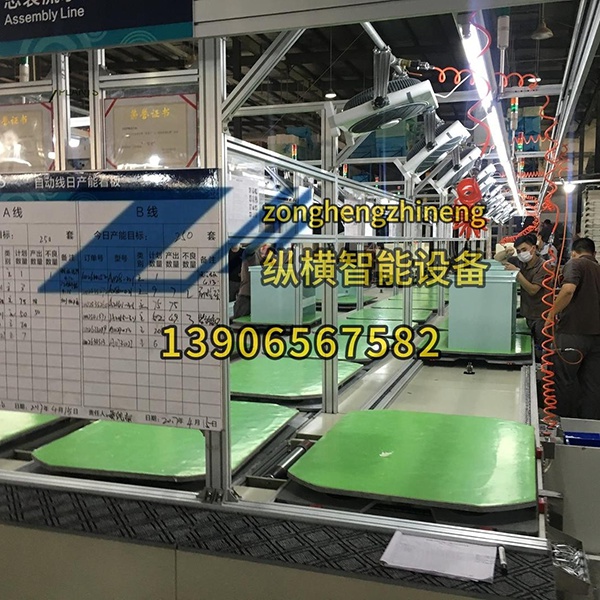

Oven Assembly Line

Oven assembly line is an automated production line for final assembly and assembly of ovens. It seamlessly connects separate processes to achieve high efficiency and high quality continuous production.

Details

1. Composition

The oven automatic assembly line and kitchen oven assembly line share a modular composition, with the digital stainless steel oven assembly line featuring specialized upgrades.

Conveyor system: In kitchen oven assembly line, continuous conveyor chains (Teflon mesh belt/plate chain) enable uniform baking for oven cavities, while digital stainless steel oven assembly line uses food-grade stainless steel belts for corrosion resistance. The system ensures relative motion between products and heating elements (electric/direct-fired rods), critical for oven automatic assembly line efficiency.

Heating system: High-quality far-infrared lamps (40,000+ hours lifespan) power kitchen oven assembly line, while digital stainless steel oven assembly line integrates precision heating zones for advanced temperature zoning.

Temperature control system: Intelligent PID control (±3℃ accuracy, ±1℃ for premium lines) ensures consistency in oven automatic assembly line, with digital stainless steel oven assembly line offering IoT-connected real-time monitoring.

Ventilation system: Blower motors and circulation fans in kitchen oven assembly line ensure uniform heat distribution, while digital stainless steel oven assembly line adds HEPA filters for cleanroom-grade air quality.

Frame & shell: steel oven assembly line uses 304 stainless steel frames (phosphate-treated, electrostatic powder-coated), enhancing durability for commercial use, while standard lines in oven automatic assembly line adopt cold-rolled steel.

2. Features

Continuous production

Oven automatic assembly line achieves 24/7 operation, reducing manual intervention by 70%—a key driver of labor cost saving. Kitchen oven assembly line optimizes conveyor speed (0.5-5m/min variable) for batch baking, while digital stainless steel oven assembly line supports mixed-model production with quick-change tooling (changeover time <20min).

Uniform temperature

Multi-segment PID control in kitchen oven assembly line ensures ±2℃ precision, critical for baking delicate components in stainless steel oven assembly line (e.g., sensor-equipped smart ovens). This reduces rework and boosts labor cost saving by minimizing quality issues.

Flexible adjustment

Frequency-converted conveyor speeds in oven automatic assembly line adapt to cookies, batteries, or packaging materials. oven assembly line adds touchscreen interfaces for recipe storage, enabling quick switching between bread baking and industrial curing—ideal for multi-product facilities targeting labor cost saving.

Energy-saving design

Waste heat recovery in kitchen oven assembly line cuts energy use by 15%, while oven assembly line integrates solar-powered ventilation, further reducing operational costs alongside labor cost saving from automated monitoring.

3. Application Scene

Food processing: Kitchen oven assembly line bakes sweet potatoes/peanuts with consistent caramelization (color deviation <5%), while oven assembly line produces premium artisanal bread with IoT-monitored crust texture, both enhancing efficiency and enabling labor cost saving.

Electronic manufacturing: In battery production, oven automatic assembly line cures electrodes with ±1℃ precision, improving yield by 8%. Digital stainless steel oven assembly line’s anti-static design suits sensitive components, reducing manual handling errors.

Packaging & printing: Kitchen oven assembly line dries glue on packaging boxes at 60-120℃, cutting breakage rate from 10% to 2%. Labor cost saving is achieved via automated defect detection (vision systems identify glue inconsistencies).

Industrial applications: Oven automatic assembly line supports paint curing in automotive lines, while steel oven assembly line handles medical device sterilization cycles, demonstrating versatility across sectors prioritizing labor cost saving.