Stove Assembly Line

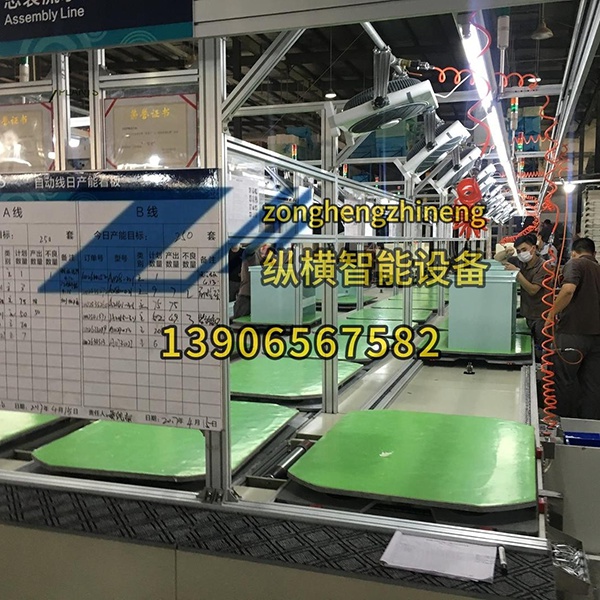

A cooker assembly line is an automated assembly line used to produce cookers. It consists of a number of workstations where workers or robots perform specific tasks to assemble parts into hob products.

Details

1.Technical composition and core function

The stove automatic assembly line usually consists of three technical units, namely, power conveying system, automatic assembly station and quality inspection module. This system is also applicable to the assembly of various kitchen implements assembly line and cooking utensils assembly line. The power system adopts chain plate line or speed chain conveying technology, which can realize the accurate positioning and continuous flow of the cooker bottom shell, panel and other parts in stove production, as well as components of other kitchen utensils; the assembly station is equipped with mechanical arm, automatic screw - locking machine and other equipment, which can complete the core processes such as burner installation and electric circuit connection for stoves, and similar key assembly processes for kitchen implements and cooking utensils; and the detection module can monitor the ignition performance and safety parameters of the cooker in real time through the gas tightness tester, flame sensor and other equipment. For example, a well - known brand's stove automatic assembly line, which also serves as part of its kitchen implements assembly line and cooking utensils assembly line, adopts AI visual inspection system, which can increase the product defect recognition rate to 99.7%.

2.Process and quality control

The process flow of a typical stove automatic assembly line, as well as common kitchen implements assembly line and cooking utensils assembly line, contains four major links: parts pre - processing, modular assembly, function testing, and packaging and warehousing. In the pre - processing stage, laser cutting, CNC bending and other processes are used to ensure the dimensional accuracy of the cooker panel in stove production, as well as parts of kitchen utensils; the assembly link adopts the “one person, one machine” mode, where workers are responsible for specific processes to reduce operational errors in the assembly of stoves, kitchen implements, and cooking utensils; the functional testing link sets aging test, pressure test and other 12 testing items to ensure that the product meets the national energy - efficiency standards across different product types; the packaging link adopts shock - proof materials and automated palletizing technology to reduce transportation losses for all products. Data show that the standardized assembly line can reduce the defective rate of products from 5% of manual production to less than 0.3%, whether it is for stoves, kitchen implements, or cooking utensils.

3.Industry Application and Typical Cases

In the field of commercial kitchen equipment, assembly line technology has realized the integrated production of stoves, steamers, ovens, and other products on kitchen implements assembly line, cooking utensils assembly line, and stove automatic assembly line. For example, an enterprise customized a “three - in - one” assembly line for chain restaurants, which can be used for stove production, as well as the assembly of various kitchen implements and cooking utensils. Through the modular design, it can achieve rapid switching of different functional modules, increasing production efficiency by 40%. In the civilian cooker market, a head brand adopts U - shaped assembly line layout for its stove automatic assembly line, which also contributes to its kitchen implements and cooking utensils assembly, compressing the production cycle of a single cooker from 12 minutes to 7.5 minutes, with an annual production capacity of more than 2 million units. These cases show that the assembly line technology is promoting the manufacturing of stoves, kitchen implements, and cooking utensils to scale and customization directions.

4.Technology trends and innovation direction

The future assembly lines, including stove automatic assembly line, kitchen implements assembly line, and cooking utensils assembly line, will present three major technology trends: First, intelligent upgrade, through 5G + industrial Internet to achieve equipment interconnection and data collection, to build a digital twin factory; Second, flexible transformation, the use of reconfigurable tooling and AGV trolleys, to support multi - species, small batch production for various products; Third, the green transformation, the introduction of waste heat recovery system and water - based paint spraying line, reduce energy consumption per unit of output value across different product manufacturing.