Drying Rack Production Line

Drying rack production line is a highly integrated and automated system that requires precise operation and strict quality control at every step, from raw material handling to finished product shipment. By adopting advanced manufacturing technology and equipment, we can effectively improve production efficiency, reduce costs, and ensure product quality meets market demand.

Details

1.Functions and core equipment

Core Functions

Parts Processing: Finish cutting, press molding (e.g. hooks, brackets), welding (e.g. welding of drying rack main frame) of stainless steel drying rack production line tubes/plates, ensuring precision for both clothing rack production line and indoor clothes drying rack production line requirements.

Surface treatment: Rust removal, phosphating, electrostatic spraying or electrophoresis treatment of parts through spraying line to improve corrosion resistance and aesthetics, crucial for premium drying rack products in both residential and commercial applications.

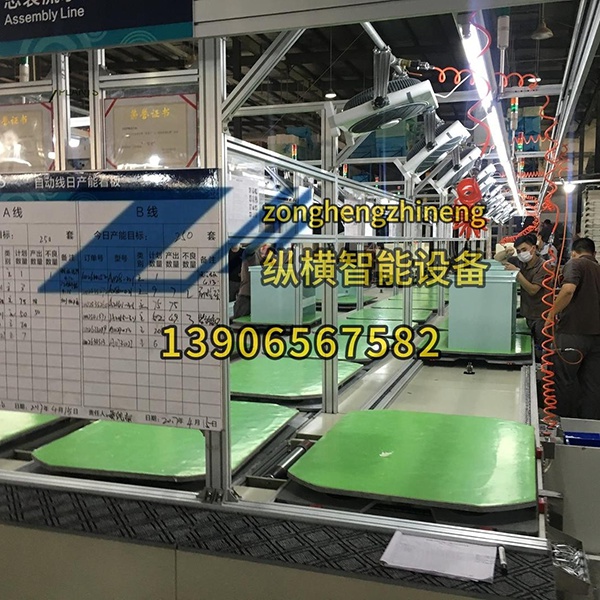

Intelligent assembly: The drying rack automatic production line realizes automatic positioning, screw locking and function testing (such as load-bearing test, lifting smoothness test) of components (such as drying pole, lifting device, control system).

Packaging and labeling: Folding/storing and buffer packaging (e.g. bubble film, carton) for finished products from the indoor clothes drying rack production line, and printing and pasting product labels (including model number, load-bearing parameters, and instructions for use).

2.Production Process Analysis

Typical Processes

Pre-treatment of raw materials

Pipes/plates are unwound by uncoiler, straightened by straightening machine, and processed by CNC cutting machine into parts of specified lengths (e.g. drying poles, brackets) for the stainless steel drying rack production line.

Parts Processing

Stamping: Metal sheets are stamped into standard parts such as hooks and end caps by molds for the clothing rack production line, and non-conforming parts are automatically rejected by sorting devices.

Welding: In the drying rack automatic production line, robots grab parts to be welded, complete frame welding according to preset trajectory, with visual inspection systems checking weld quality.

Surface treatment

Parts enter the spraying line through suspension chain, going through degreasing tank, pickling tank, electrostatic spraying room, and drying oven (180-200℃ curing) to form wear-resistant surfaces - a critical step for indoor clothes drying rack production line quality.

Intelligent assembly

The drying rack automatic production line is divided into several stations:

Basic assembly: Manual or mechanical arm fixes drying pole, bracket on working table, automatically locking screws for consistent clothing rack production line output.

Function integration: Installation of motor, wire rope and remote control modules for electric drying racks, with circuit connection testing.

Finished product test: Function tests for load bearing, lifting speed, overload protection on test bench, with unqualified products flowing to rework station.

Packaging and storage

Qualified products from the indoor clothes drying rack production line are folded, bubble-wrapped, packed into branded cartons, sealed and conveyed to palletizing area where robots place them on pallets for AGV transport to warehouse.

3.Core Advantages

Efficient production capacity: The drying rack automatic production line achieves 5-8 second cycle times (for simple drying racks), with annual capacity of 500,000-1,000,000 units - 3-5× traditional manual lines.

High precision and consistency: Key processes in stainless steel drying rack production line maintain ≤±0.5mm dimensional accuracy with <0.3% failure rate.

Flexible changeover: The clothing rack production line can switch between manual/electric models in 30 minutes via quick mold/program changes, enabling small-lot customization.

Cost Optimization: Drying rack automatic production line reduces labor by 60-70%, energy use by 20%, and scrap rate from 5% to <1.5%.

Intelligent management: MES integration enables real-time monitoring of equipment status, production progress and quality data across all drying rack production lines.

4.Applicable Scenarios and Cases

Applicable product types

Household drying racks: Floor-standing, folding models from clothing rack production line.

Intelligent drying racks: Electric lifting, UV disinfection units from advanced drying rack automatic production line.

Commercial drying racks: Large stainless steel drying rack production line units for hotels/apartments.