Drying Rack Assembly Line

Through highly automated and intelligent design, combined with advanced production equipment and technological innovation, the drying rack assembly line is able to efficiently produce high quality drying racks while enhancing user experience.

Details

1. Core Composition of Drying Rack Assembly Line

Raw Material Pretreatment Area

Function: Pre-treatment of metal pipes (stainless steel, aluminum alloy) or plastic granules by cutting, punching, and injection molding for drying rack production.

Equipments: Laser cutting machine, hydraulic punching machine, injection molding machine (for plastic clothes drying rack assembly line), pipe straightening machine.

Parts Processing Area

Function: Produce connectors, pulleys, springs, and hooks for drying racks, ensuring compatibility with both manual and drying rack automatic assembly line setups.

Equipments: CNC lathe, milling machine, tapping machine, automatic assembly machine (for pre-assembly of spring and hook in steel wire drying rack assembly line).

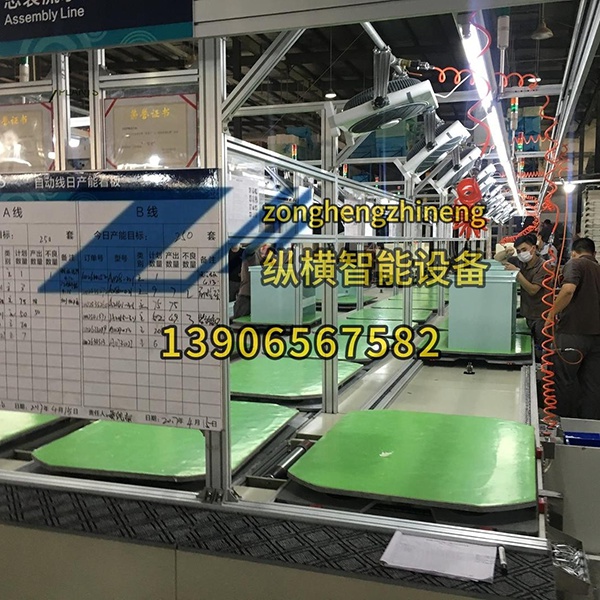

Assembly Line

Function: Assembling pre-treated pipes and accessories into complete drying racks, whether for standard models or specialized clothes drying rack assembly line variants.

Equipment:

Manual assembly station: Workers handle screw tightening and pulley installation for customized drying racks.

Automated assembly module: Robots perform high-precision tasks like welding crossbars and columns, essential for drying rack conveyor assembly line efficiency.

Surface Treatment Area

Function: Enhance corrosion resistance and aesthetics via electroplating, spraying, or oxidizing, critical for both steel wire assembly line and plastic models.

Equipments: Electrostatic spraying line, plating tank, drying furnace, and waste gas treatment devices (compliant with drying rack automatic assembly line environmental standards).

Quality Inspection and Packaging Area

Function: Test load-bearing, structural strength, and surface defects before packaging drying racks for shipping.

Equipment:

Inspection: Load-bearing test machine, visual inspection system (for scratches/burrs, especially in clothes drying rack assembly line).

Packing: Automatic baler, labeling machine, and carton molding machine for secure transport.

2. Production Process

Example: Metal Elevating Drying Rack

Tube Cutting: Laser cutting segments stainless steel tubes to design size for drying rack frames.

Punching and Bending: Hydraulic punching machines create screw holes, while bending machines shape arms for steel wire drying rack assembly line models.

Accessories Pre-installation: Automated equipment installs pulleys, springs, and hooks—key for drying rack automatic assembly line speed.

Main Body Welding: Robot welding ensures precision for drying rack main structures, vital in high-volume drying rack conveyor assembly line setups.

Surface Treatment:

Electroplating: Chrome plating for rust resistance (common in steel wire drying rack assembly line).

Spraying: Electrostatic spraying offers colors (e.g., matte black) for clothes drying rack assembly line aesthetics.

Assembly and Commissioning: Manual installation of crossbars and hand cranks, followed by lifting tests—critical for drying rack functionality.

Quality Inspection and Packaging:

Load-bearing test: 50kg weight for 24 hours (ensuring drying rack durability).

Packing: Anti-collision foam + color box + carton for drying rack conveyor assembly line shipping safety.

3. Technical Features and Advantages

Automation + Flexible Production

Automation: Unmanned welding/spraying boosts efficiency by 30% in drying rack automatic assembly line.

Flexibility: Quick mold changes allow production of varied drying racks (single/double pole, hand crank/electric).

Modularized Design

Standardized interfaces for crossbars, columns, and hand cranks simplify assembly in clothes drying rack assembly line and repair.

Environmental Protection & Energy Saving

Exhaust treatment: RTO incinerators (VOCs removal ≥95%) in drying rack conveyor assembly line spraying zones.

Energy-saving motors: Permanent magnet motors cut energy use by 20% in steel wire drying rack assembly line drives.