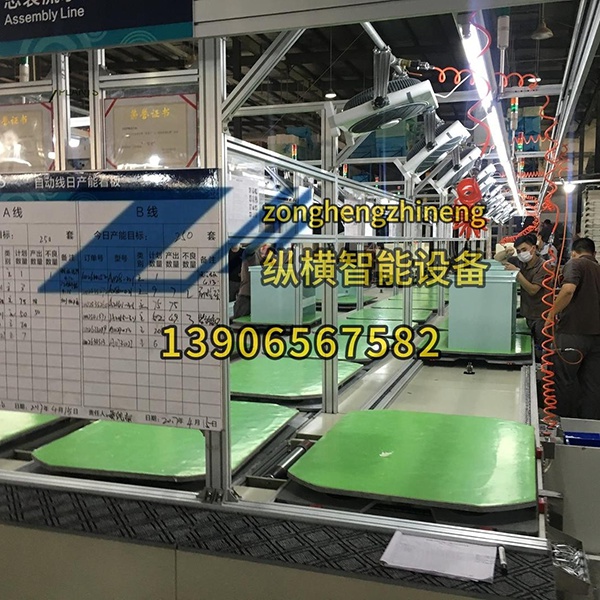

Cosmetic Mirror Production Line

Cosmetic mirror production line is a complex system involving multiple links such as design, R&D, production and sales. Each link requires fine operation and strict quality control to ensure high quality and good performance of the final product.

Details

1.Production Segment

The make-up mirror production line begins with:

Preparation of raw materials: Procuring metal, glass, and plastic materials according to product specifications. For instance, in a dressing mirror production line, metal plates are precision-cut for frames while glass meets optical standards.

Parts processing:

Lens processing: Glass cutting/grinding/polishing ensures dimensional accuracy - a critical step in cosmetic mirror automatic product line quality control.

Bezel Processing: Metal stamping/bending (for make-up mirror production line frames) or plastic injection molding (common in dressing mirror production line designs).

Other parts: Light strips and circuit boards are fabricated to match cosmetic mirror automatic product line electrical specs.

Assembly link:

Lens-frame integration: Special adhesives secure lenses in frames, a process standardized across make-up mirror production line variants.

Functional components: LED strips and switches are installed with precision, meeting dressing mirror production line illumination requirements.

Quality Inspection: Rigorous checks ensure cosmetic mirror automatic product line outputs pass scratch/functionality tests.

Packaging: Shock-proof materials protect finished products from both make-up mirror production line and dressing mirror production line.

2.Technical Features

The cosmetic mirror automatic product line demonstrates:

Automation: Glass cutting machines and injection molders maintain ±0.1mm tolerances in make-up mirror production line operations.

Customization: Dressing mirror production line configurations adapt to sizes from compact 20cm to salon-style 50cm mirrors.

Detail focus: Seamless frame joints (critical for cosmetic mirror automatic product line luxury models) achieve <0.5mm gaps.

3.Development Trend

Intelligent production: Intelligent equipment and systems are introduced to realize automated monitoring and management of the production process and improve production efficiency and product quality. For example, real-time monitoring of the operating status of production equipment through sensors, timely detection and resolution of problems.

Green: Adopt environmentally friendly materials and processes to reduce pollution and waste in the production process. Such as the use of biodegradable packaging materials, optimize the production process to reduce energy consumption.

Multi-functional integration: The functions of makeup mirrors are constantly enriched, such as integrating Bluetooth speakers, wireless charging, etc., to meet the diversified needs of consumers. The production line needs to continuously adapt to the upgrading and changes in product functions.