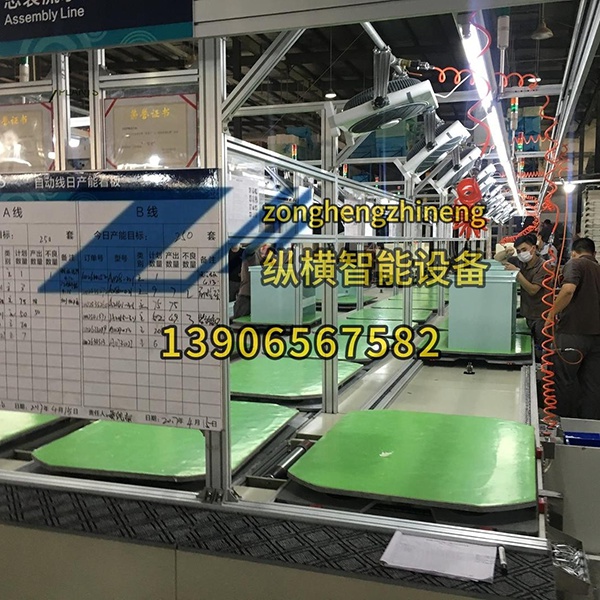

Cosmetic Mirror Assembly Line

The production process of cosmetic mirror assembly line involves several links, including material selection, processing, assembly, inspection and packaging.

Details

1.Components

The dressing mirror assembly line integrates the following core modules to ensure precision manufacturing:

Manually discharging mechanism: Places raw materials for make-up mirror assembly line production at designated positions, preparing for subsequent assembly.

Assembling mechanism: Includes card spring, buffer pad, and contact piece mechanisms, critical for cosmetic mirror automatic assembly line part integration.

Detecting mechanism: CCD system performs full inspection on assembled mirrors, essential for both bathroom fittings assembly line and cosmetic mirror quality control.

Welding Component: Hot-melt welding with adjustable parameters ensures durability, a standard in dressing mirror assembly line and make-up mirror assembly line processes.

Carrying module: Transfers mirrors between stages, a universal feature in cosmetic mirror automatic assembly line automation.

Mirror cover handling components: Oiling and opening mechanisms meet bathroom fittings assembly line and cosmetic mirror.

Bulb assembly mechanism: Automates bulb installation with conduction testing, vital for make-up mirror assembly line functionality.

Finished product discharging: Completes the mirror automatic assembly line cycle by ejecting qualified products.

2.Workflow

The make-up mirror assembly line follows this optimized workflows:

Unloading: Operators place shells, lenses, and circuit boards at manual stations, a first step in dressing mirror assembly line and bathroom fittings assembly line production.

Assembly: Sequential part integration via preset programs, mirroring cosmetic mirror automatic assembly line precision.

Welding: Heat fusion secures connections, a shared standard across bathroom fittings assembly line and mirror production.

Carrying: Modules transfer semi-finished products, ensuring make-up mirror assembly line continuity.

Lid Handling: Oiling and opening prepare covers for testing, critical in dressing mirror assembly line cosmetics models.

Bulb assembly/testing: Automated installation and checks guarantee cosmetic mirror automatic assembly line performance.

Inspection: CCD verifies appearance and function, a universal phase in bathroom fittings assembly line quality control.

Finished product discharge: Qualified mirrors exit the make-up mirror assembly line for packaging.

3.Advantageous Features

The cosmetic mirror automatic assembly line offers:

Efficient production: Single-operator material loading, shared by dressing mirror assembly line and bathroom fittings assembly line, cuts labor costs.

Stable quality: Precision assembly and testing ensure make-up mirror assembly line output consistency.

High automation: Full-process automation from loading to ejection, a hallmark of cosmetic mirror automatic assembly line systems.

Flexibility: Rapid reconfiguration supports diverse products, from bathroom fittings assembly line components to luxury mirrors.